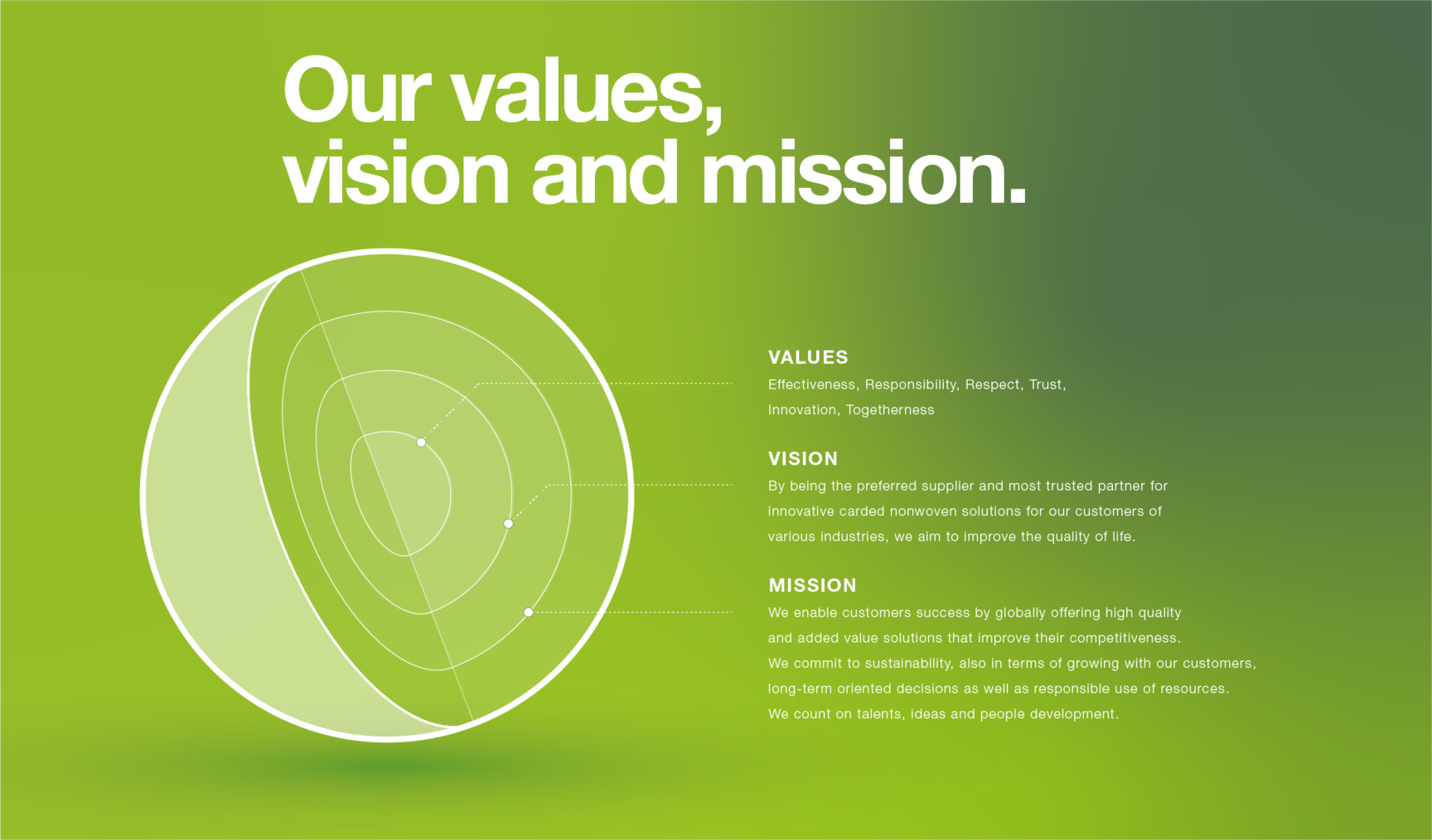

'For TWE, sustainability will become an integral part of our very existence.

Throughout our entire worldwide organisation,

Corporate Social Responsibility (CSR) will be the driving force behind

our strategy and our mission...'

'For TWE, sustainability will become an integral part of our very existence.

Throughout our entire worldwide organisation,

Corporate Social Responsibility (CSR) will be the driving force behind

our strategy and our mission.

Starting from the creation of an idea for a new product,

Design For Environment (DFE) will be embedded in our Research & Development

approach, always meeting performance and cost objectives.

We will strive for seeking technological solutions with the least environmental

impact and respect for the use of natural resources so they will fit within the planetary boundaries in order to preserve our civilisation for future generations.

At the same time we pledge to develop a social foundation for our stakeholders such as employees, shareholders, communities, etc., in order to become the responsible employer of choice.'