Our Laboratories

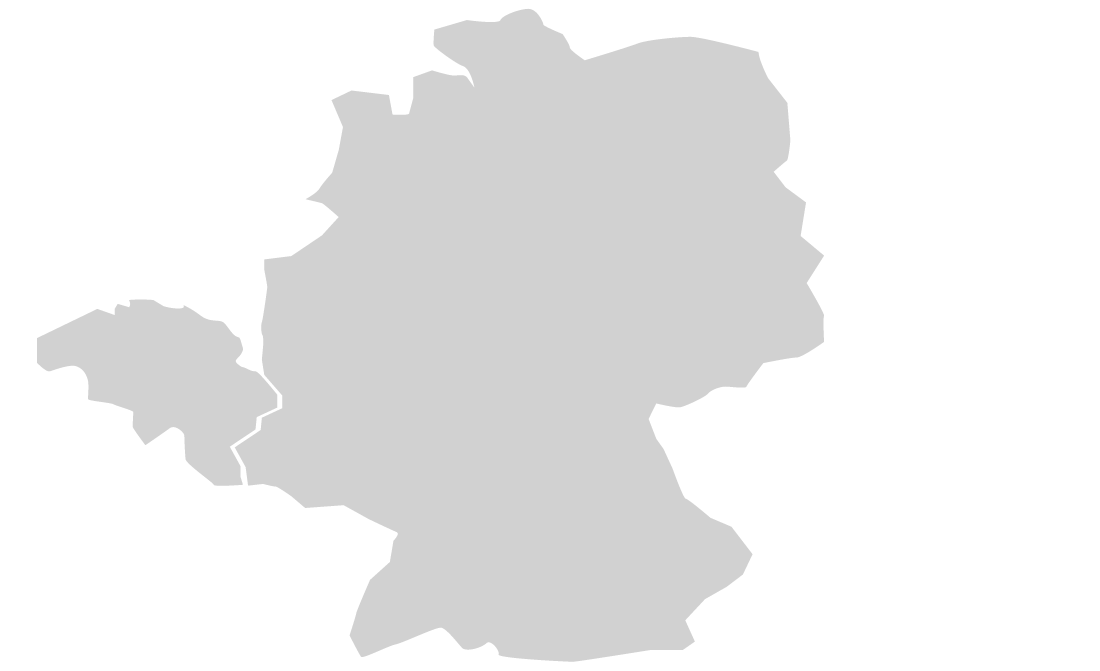

Choose a laboratory location on the map and learn more about our innovations.

TWE Meulebeke BVBA

Marialoopsteenweg 51

8760 Meulebeke

Tel: +32 51 426 800

Fax: +32 51 426 700

info@twe-group.com

TWE Dierdorf GmbH & Co. KG

Poststraße 29

56269 Dierdorf

Tel: +49 2689 92 0

Fax: +49 2689 92 6663

info.dierdorf@twe-group.com

TWE Vliesstoffwerke GmbH & Co. KG

Hollefeldstraße 46

48282 Emsdetten

Tel: +49 2572 205 0

Fax: +49 2572 205 80

info.emsdetten@twe-group.com

TWE Rudolstadt GmbH

Breitscheidstrasse 156,

07407 Rudolstadt

Tel: +49 3672 31990

Fax: +49 3672 3199-20

info.rudolstadt@twe-group.com

Tests & Methods{{{ customTitle }}}

In order to respond to our customers requirements and guarantee the high quality of our product, the properties of TWE Group nonwovens are assessed using a variety of test methods

{{{ item.beschreibungstext }}}

{{ item.linkTitel }}

{{ item.linkTitel }}

{{{ item.beschreibungstext }}}

{{{ item.beschreibungstext }}}

© TWE GmbH & Co. KG, 2025

Sitemap